CASE STUDY

A corrosive environment resulted in the premature degradation of two 100,000 cfm air handlers at a petroleum refining facility. The end user, an integrated energy company with global operations, had made many changes to their processes during the lifetime of the equipment. As a result, the project specifications called for a doubling of air flow and heating capacity while adhering to strict space constraints.

Process engineers requested additional features including specific sensors and controls which would provide strictly controlled and verified air flows. Adherence to complex control narratives was mandatory in order to meet varying operating conditions. System purge and shutdown modes were incorporated into the automation system based on H2S and SO2 gas detection levels detected using sensors mounted on the exterior of the air handlers.

Southampton worked closely with the client throughout this critical project to make design changes during fabrication as site engineers uncovered new issues. In order to simplify installation at the job site, the two internal air streams were reconfigured from a side discharge arrangement to a common down discharge air plenum. Other changes included the relocation of steam piping connections as well as reducing the overall weight by changing construction materials to aluminum wherever possible.

Features include:

- Two replacement air handlers with remote control panel

- 200,000 cfm per unit

- Two 100 hp supply fan motors per unit

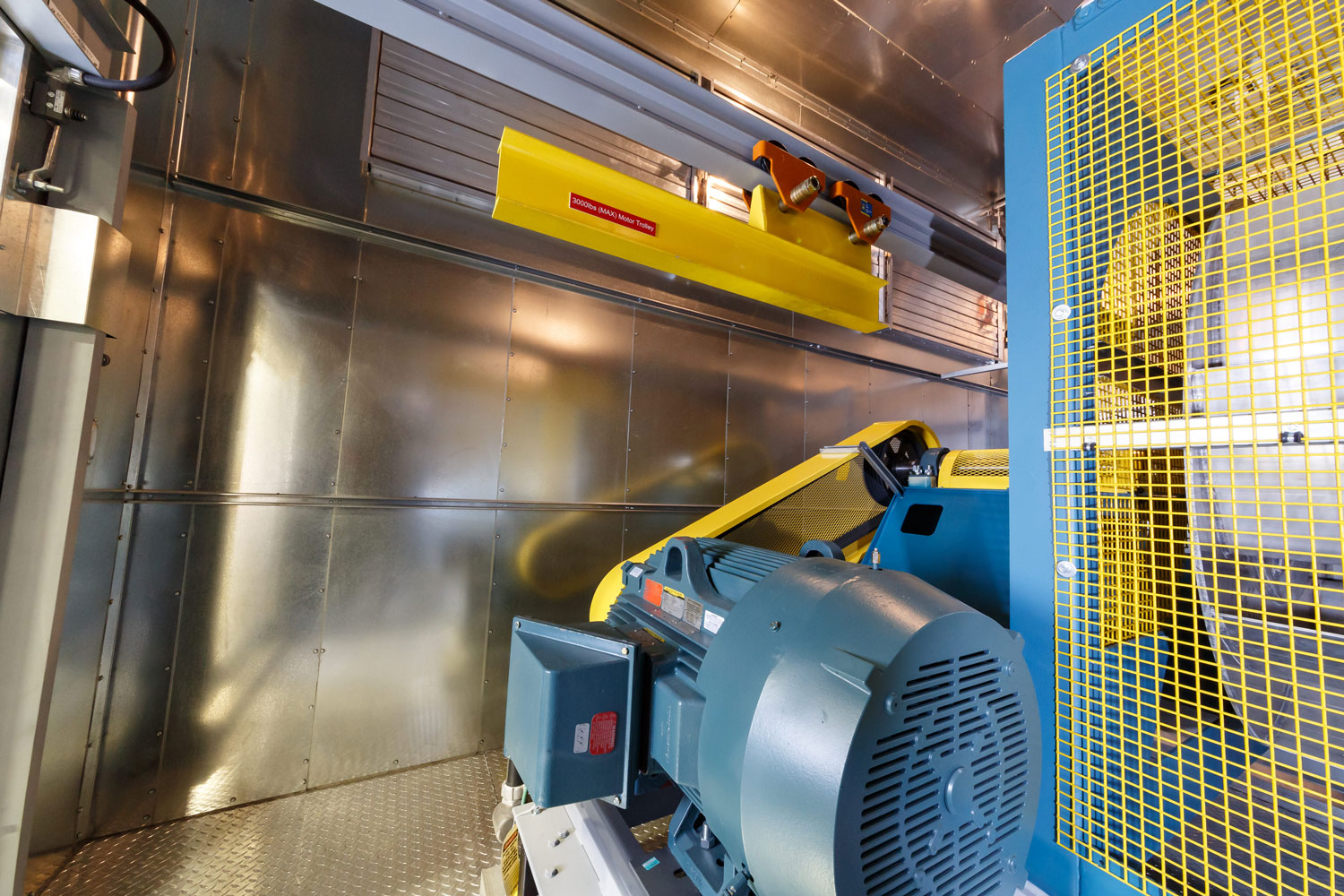

- Motor removal rails

- Four inch casings

- Factory witness testing

- Witnessed integration testing with building control panel hard wired to air handlers

- Air flow measuring and verification system

- Steam heating with CRN steel coils

- H2S and SO2 gas detection (high and low LEL conditions)

- Fire/gas shutdown controls with strobe alarms

- Purge, recirculation and pressurization capabilities

- Heated vestibule with automation panels and VFD’s (see 360° view)

MOTOR REMOVAL RAIL SYSTEM

ELECTRICAL AND CONTROL PANEL VESTIBULE